Why Fiber Laser Engraving is Transforming Metal Engraving at Custom Crafted

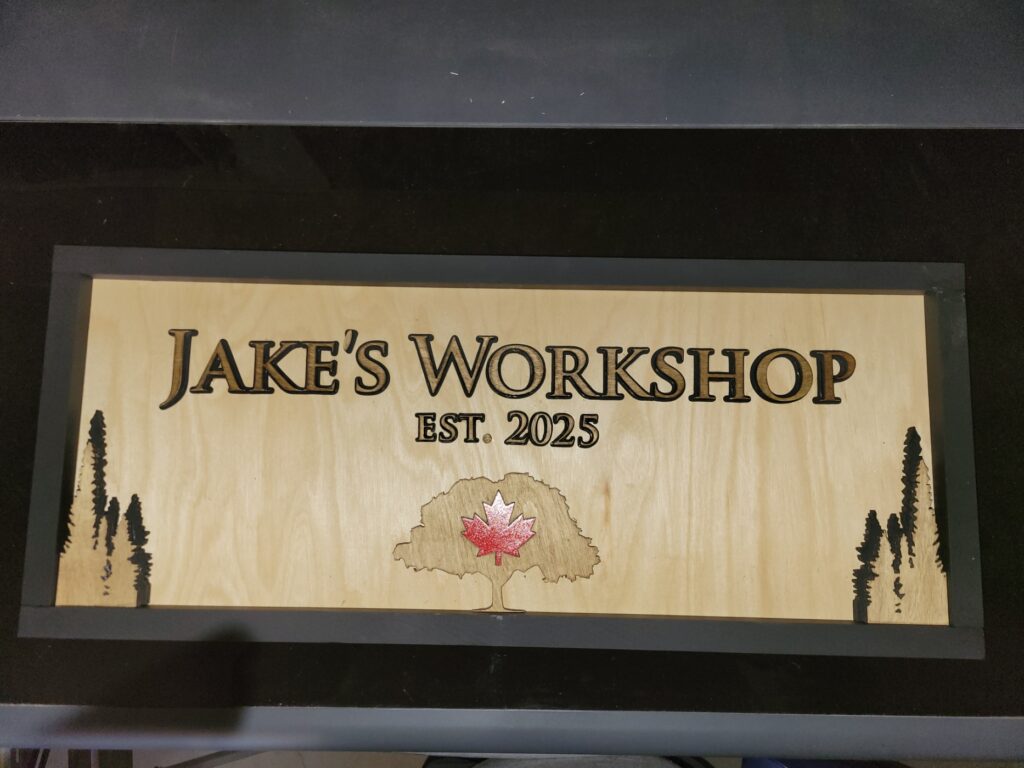

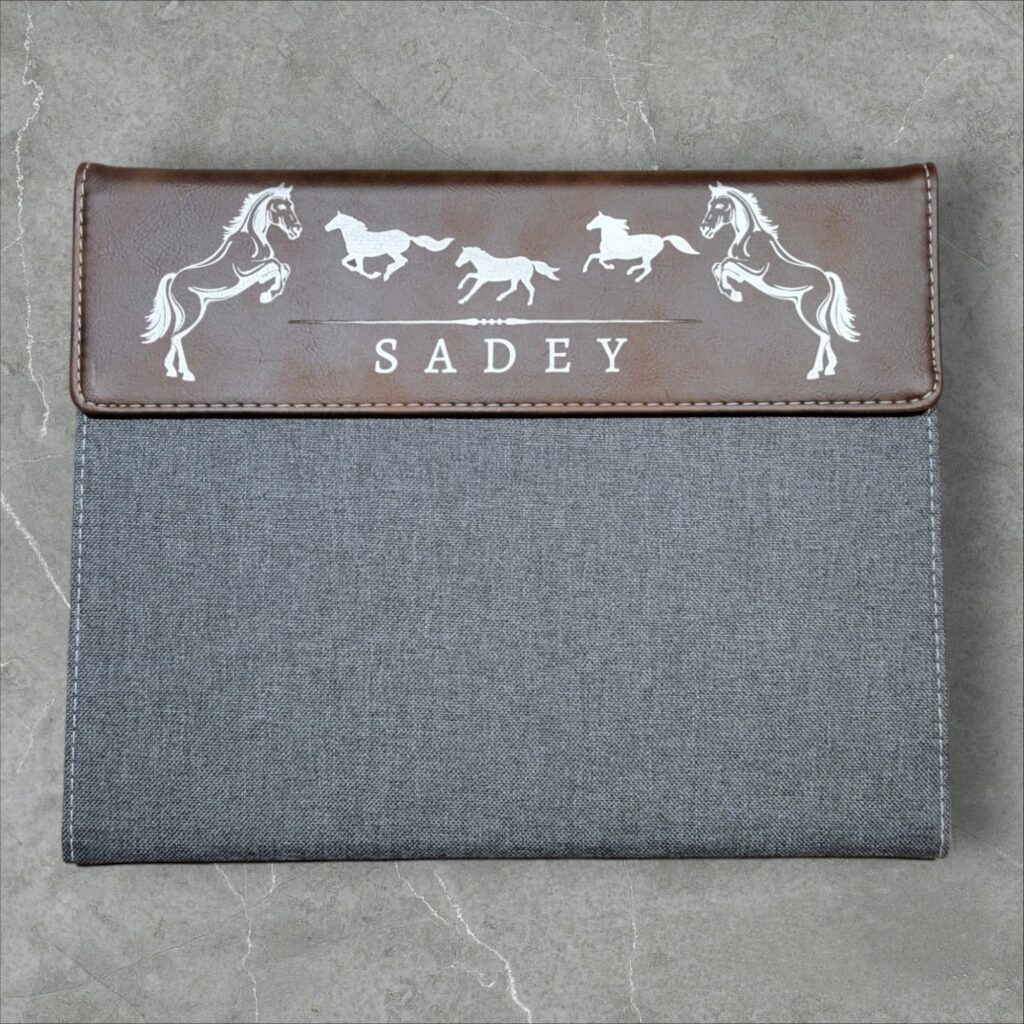

As an entrepreneur navigating the fast-paced world of custom manufacturing, I’ve seen how the right technology can make or break a business. That’s why I’m excited about what’s happening here at Custom Crafted Calgary, a dynamic small business in Calgary, Alberta, that’s elevating metal engraving with a powerful fiber laser. Our new GWeike G2 50W Max features specs like 50W output, a 1064nm wavelength, and a 150mm x 150mm marking area, this machine is a game-changer for custom laser engraving. From industrial components to personalized keepsakes, Custom Crafted is leveraging this tech to deliver precision, efficiency, and quality. Let’s dive into why fiber laser engraving is revolutionizing our approach to metal engraving and setting a new standard in Calgary’s vibrant market.

Precision That Redefines Quality

When it comes to metal engraving, precision is non-negotiable. This fiber laser delivers with an impressive ±0.001mm repeat accuracy, allowing Custom Crafted to create intricate designs with unmatched clarity. Whether it’s etching tiny serial numbers on industrial parts or crafting detailed logos on jewelry, the machine’s focused 1064nm beam ensures sharp results without distorting the metal. Unlike traditional mechanical engraving, which can leave rough edges or burrs, this laser produces clean, professional finishes.

For Calgary’s diverse clientele—from energy sector companies needing durable markings to artisans seeking bespoke designs—this precision is a major win. The minimal heat-affected zone prevents warping, ensuring every piece meets exacting standards. It’s the kind of reliability that builds trust and sets Custom Crafted apart in a competitive market.

Speed That Drives Efficiency

In a startup like Custom Crafted, time is everything. This laser’s marking speed of up to 15,000mm/s means we can handle high-volume orders without sacrificing quality. From batch-processing promotional items to engraving custom industrial tags, the non-contact process eliminates tool wear and reduces setup time. Designs are programmed via software, streamlining workflows in our Calgary workshop.

The 50W power ensures deep, consistent engravings while keeping energy use low, which is a big plus for operational costs. For a company looking to scale, this efficiency translates to faster turnarounds and happier clients, whether they’re local businesses or individuals seeking custom laser engraving. It’s a practical edge that fuels growth.

Versatility for Every Metal Engraving Need

One of the standout features of this laser is its versatility. It handles a wide range of metals—stainless steel, aluminum, brass, copper, gold, and even reflective alloys—without needing special coatings. This flexibility is perfect for Calgary’s mix of industries, from oil and gas to creative arts. Custom Crafted uses it to engrave traceability codes on pipeline components, create custom awards, or add intricate designs to jewelry. We have also used this new laser to engrave names into skate blades as well as a company logo into an 8.8lb stainless steel beer stein!!

Durability That Stands the Test of Time

For metal engraving, longevity matters. This laser creates deep marks—up to 5mm—that resist abrasion, chemicals, heat, and Alberta’s tough weather conditions. Unlike temporary solutions like printed labels, these engravings are permanent, becoming part of the metal itself. This is crucial for industries requiring compliant, traceable markings or businesses wanting branding that lasts.

Custom Crafted’s clients, from manufacturers to gift shops, benefit from engravings that stay legible for years, reducing rework and boosting satisfaction. Whether it’s outdoor signage or heavy-duty equipment, the durability ensures their work holds up in any environment.

Cost-Effective and Low-Maintenance Operations

Running a business in Calgary means keeping costs in check, and this laser delivers. With a long service life and no need for consumables like inks or blades, maintenance is minimal. Its energy-efficient design keeps power bills manageable, even with high output. Compared to chemical etching, which involves costly waste disposal, this method is cleaner and more economical.

For Custom Crafted, this means we can offer competitive pricing on small-run custom laser engraving projects, appealing to startups, local artists, and individuals. The investment in this technology is already paying dividends by enabling efficient, high-quality production without breaking the bank.

Eco-Friendly and Safe for Modern Workspaces

Sustainability is a priority in 2025, and this laser aligns with Custom Crafted’s commitment to green practices. It generates minimal waste, avoiding the environmental impact of chemical processes. The non-contact engraving method also enhances safety, reducing risks for their team in Calgary. Built-in safety features ensure smooth, worry-free operation, letting them focus on delivering exceptional metal engraving.

Outshining Other Engraving Methods

Compared to alternatives, this fiber laser is a clear winner. CO2 lasers struggle with metals without additives, and mechanical engraving is slow and prone to errors. Chemical etching is messy and less precise. With its speed, accuracy, and ability to handle any metal, this machine gives Custom Crafted a distinct edge in custom laser engraving, making it the go-to choice for their clients.

Conclusion

Custom Crafted is redefining metal engraving in Calgary with their new fiber laser. Its 50W power, 15,000mm/s speed, and ±0.001mm precision enable them to deliver custom laser engraving that’s precise, efficient, and built to last. From industrial applications to artistic creations, this technology is helping us meet diverse needs while keeping costs low and operations sustainable. For businesses and creators looking to stand out, fiber laser engraving is the future—and Custom Crafted is leading the charge in Alberta.